Research program in

Research program in

electrochemical processes

Sweden has an important electrochemical industry. Eka Nobel

Elektrokemi AB, which has its head office in Stockholm and

production units spread throughout the country, is the

world's leading producer of, among other things,

environmentally friendly bleaching agents for use in the

paper-manufacturing industry. Zinc is produced by the

Norwegian company Norzink AS, of which Boliden Metall AB

owns 50%. These companies will be industrial partners in the

Centre of Excellence for the Fluid Mechanics of Industrial

Processes.

The electrochemical processes for the production of zinc and

bleaching agents, such as sodium chlorate, are in some

respects very similar. Electrolysis takes place in baths of

electrolyte in so-called electrolysers, in

which a number of electrodes are immersed, coupled either in

series or in parallel. Due to the reactions at the

electrodes the concentration field varies in space, with the

result that the electrolyte's weight (per unit

volume) will be locally either less than or greater than the

average weight in the bath. Consequently the electrolyte is

set in motion by the force of gravity, light electrolyte

rises while heavy electrolyte sinks. This motion is nearly

always turbulent. Furthermore, in the production of sodium

chlorate hydrogen gas is generated at the cathode and in the

zinc electro-winning process, oxygen gas is evolved at the

anode. Due to the friction between the bubbles and the

electrolyte, the upwards motion of the bubbles of gas causes

turbulent circulation of the electrolyte in the

reactor.

Many problems which are closely related to the fluid mechanical

phenomena mentioned above arise in the optimization of the

design of electrolysers. For instance, the exchange of mass

at the electrodes should be maximized, which requires a

rapid supply of undepleted electrolyte. However, high

velocities result in short residence times in the

electrolysers, which leads to a lot of electrolyte passing

through the electrolyser without being fully used. The

evolution of gas bubbles at the electrodes is often

exploited to drive the electrolyte through the electrolyser.

But a large volume fraction of bubbles increases the

electrical resistance of the electrolyte, which increases

the loss of energy. The consumption of energy is perhaps the

most critical problem in the electrochemical process

industry.

Among the long-term goals of this industry which require detailed

knowledge of, among other things, the fluid mechanics of

electrochemical processes for their achievement, it is

particularly worth mentioning;

The third goal is definitely the most important, but

also at the same time the most difficult to achieve since

all the different parts of the process interact with each

other. The first two goals are in fact essential for

achieving the third goal but can probably be closely

achieved using existing fluid mechanical methods. However,

the presence of turbulence makes it difficult to predict the

rate of mass transfer to the electrode surface which is

significant for, for example, determining the current

distribution and the current efficiency at the

electrodes.

At the Centre this sort of phenomena will be investigated

experimentally with non-intrusive velocity measurements

using Laser-Doppler Velocimetry. The turbulent concentration

fields are significantly more difficult to measure. However,

concentration measurements are possible at the electrode

surface itself using so called micro-electrodes. Theoretical

calculations will also be carried out using the L.E.S.

method which, as was mentioned above, will require a

considerable effort. The next two sections present the two

classes of problems which have to be studied using both

theoretical and experimental methods.

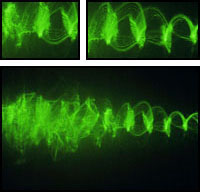

Turbulent convection between vertical electrodes Convection driven by bubbles Measurements of the size, volume fraction and motion of bubbles are

complicated. However, there are a number of favourable

factors in the applications which are considered here. The

volume fractions are not very large, which makes it less

difficult to identify individual bubbles. Furthermore, in

many cases, the bubbles are small, their velocities are not

very large and their motion only deviates slightly from a

straight line. This implies that statistical information can

be obtained using video technique and computerized image

processing. These factors will also facilitate mathematical

modelling and theoretical calculations. The theoretical

investigations will probably consist to a large extent of

advanced numerical analysis. Initially the studies will be

limited to laminar convection.

Plans for future projects within

FaxénLaboratoriet (FLA)

If the distance between the electrodes is of the order of 1 cm or

more and the height of the electrodes is greater than

approximately 1 dm then the motion of the electrolyte will

usually be turbulent. For the time being, the influence of

bubbles of, for example, hydrogen will be not be taken into

account. The turbulent motion will strongly increase the

convective transport of mass to the electrodes and will

dominate the weaker transport mechanisms of diffusion and

migration apart from in the immediate vicinity of the

electrodes. Simpler conventional computational methods for

turbulence in aerodynamic applications, such as, for

example, k-e and R.S.T. models, are not suitable in their

original forms for the sort of calculations considered here.

All the same, efforts will be made to modify these models

for electrochemical applications.

This is one of the most difficult problems considered in this

application. At the same time, this problem is one of the

most generally important areas of Chemical Engineering. This

is one of the areas in which a considerable effort will have

to be made. If any results are to be obtained at all then

only moderate demands can be placed on the precision of the

theory and the experiments.

electrochemical processes

In this branch of engineering, research is planned in a longer time

perspective into electrochemical manufacture of printed

cards for electrical circuits, called printed circuit cards

once the components have been mounted. In the technology of

copper refinement, the prediction of the formation of

nodules (dendrites) and of various blocking phenomena is

important. Further areas of interest are electrochemical

treatment of cancer and the development of efficient methods

for the production of hydrogen by electrolysis of water.

This last problem is important as a method of storing

energy. Fluid mechanics is fundamentally important in all

these studies.

Last modified:1999-04-17